I’ve recently been talking with Greg Weber – the owner of a Trotec Speedy 300 laser machine. He offered to make a posting on the blog about some of the projects he’s been working on…

Hi, my name is Greg and I’m the owner of a Trotec Speedy 300 laser machine. I love to work on various materials in my spare time on this laser cutter/engraver. I prefer wood, glass or paper and would like to share my experience with these materials with you. I mainly realise my own ideas and designs but I’m also searching the web for templates as well. I occaisonally use the ready-made designs on my machine supplier’s website. In case you’re interested, go check out http://www.troteclaser.com/EN-US-US/LASER-SAMPLES/Pages/Samples-Overview.aspx

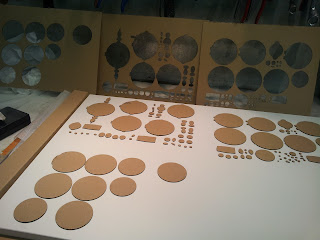

Laser engraving paper and cardboard

Paper and cardboard both can easily be processed with a laser machine to make intricate designs, beautiful patterns or decorate invitations. Compared to mechanical cutting a laser really pays off when working with paper and cardstock due to its high precision. Recently I made this paper application:

Does the paper burn while processing it with the laser?

Some of you might ask if the laser burns the paper during the cutting process. This can easily be avoided by using the correct settings on the laser machine. If you don’t know the optimal parameters I suggest asking your laser machine manufacturer for help.

Applications made from wood

According to the manufacturer almost every type of wood is suitable for laser cutting and engraving. From my experience I’d say that balsa and alder wood are the best. There are almost unlimited options what you can create from wood. I usually use wood to make gift articles, premium packaging or toys. Check out this Valentine’s Day gift I made:

What is important for processing wood?

Again the laser settings are the key to perfectly cut edges when working with wood. To find the perfect parameters you have to test them before you start with the “real” process. Therefore you should have enough wood available. If you have any problems regarding the laser parameters, I’d ask the laser machine manufacturer again.

Glass engraving

There are many possibilities regarding glass engraving. Even photos and graphics are possible. According to the manufacturer you can engrave any design on glass which can be printed.

How to engrave a drinking glass?

To engrave a wine or beer glass the glass is clamped into a rotary attachment. Make sure to set the appropriate diameter of the glass and the height of the graphic in your laser software. The software then calculates the design of your graphics for the conical surface of the glass. This is essential to get a perfect result. A CO2-laser is used when engraving glass.

I hope I was able to share some insight on working with a laser machine. Questions highly welcome ![]()

[I kinda like the glass engraving, that's something I'm going to have to try myself... - Steve]